The Easy Fold is a compact, advanced fan folding machine for labels and tickets without sprocket holes. It features innovative technology to enhance folding efficiency and precision, making it ideal for professional use.

Easy Fold is an advanced compact fan folding machine specifically designed for folding labels and

tickets without sprocket holes. This machine offers a range of innovative features to enhance

efficiency and precision in folding operations.

Key Features:

• 7” LCD Touch Screen: Provides an intuitive interface for inputting length and settings,

ensuring ease of use and precise control.

• Electronic Size Adjustment System: Allows for quick and accurate adjustments of fold

length in Z or mm, accommodating various folding requirements.

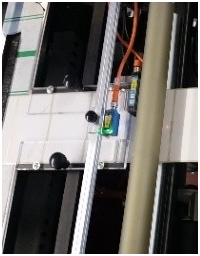

• Side Guides for Pin-less Web Feeding: Ensures smooth and accurate feeding of the web

without the need for sprocket holes.

• Gap Reader Sensor: Suitable for die-cut labels, this sensor ensures precise folding by

detecting label gaps or cue marks.

• Wheel Holder Unit with Traction Rubber Wheel: Enhances stability and control during the

folding process.

• Folder with Extraction Rollers, Beaters, and Brushes: Ensures consistent and high-quality

folding by effectively managing the paper during the process.

• Programmable Counter: Allows for accurate tracking and management of production

quantities.

• Automatic Descending Table: Adjusts automatically during production to maintain optimal

folding conditions.

• Adjustable Fold Phase Setting: Can be adjusted during production to ensure consistent

fold quality.

• CE Standards Compliance: Meets European safety and quality standards, ensuring reliable

and safe operation.

Advantages:

• Electronic Size Adjustment System: Facilitates quick and precise changes to fold sizes,

enhancing operational efficiency.

• 7” LCD Touch Screen: Offers a user-friendly interface for easy setup and control.

• Easy and Fast Setup: Designed for quick installation and minimal downtime.

• Compact Design: Saves space while providing robust folding capabilities.Technical Specifications:

• Web Width: 65-330 mm (optional 40 mm)

• Paper Weight: 70-300 g/m²

• Minimum Fold Size: 149.225 mm / Z = 47

• Maximum Fold Size: 381.000 mm / Z = 120

• Speed (Folds per Hour):

• Z = 48 (152.40 mm): 17,800

• Z = 80 (254.00 mm): 10,700

• Z = 96 (304.80 mm): 8,900

• Z = 112 (355.60 mm): 7,600

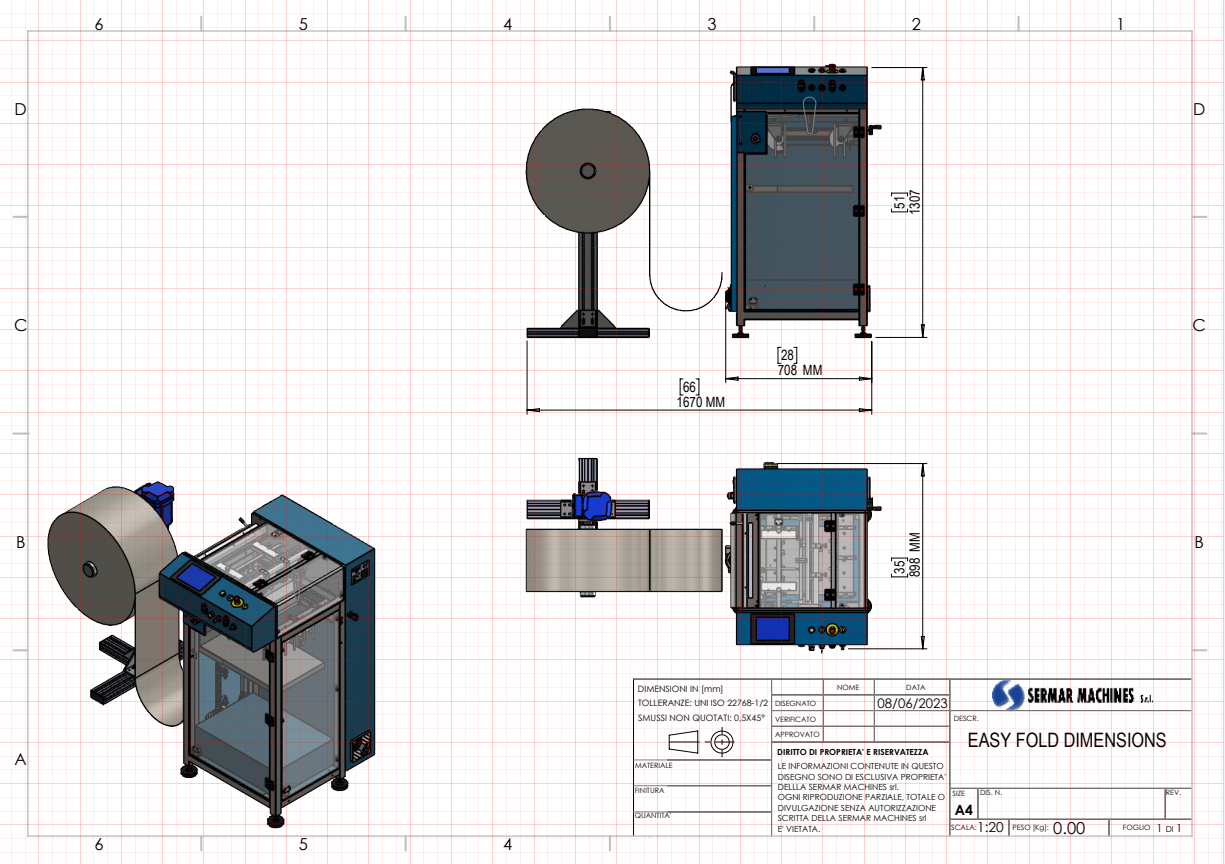

• Dimensions (WxDxH, without unwinder): 74 x 90 x 135 cm

• Weight: 200 kg

• Power Requirements: 230Vac single or 3 phase – 50/60Hz

Optional Unwinder (BASIC):

• Maximum Roll Size: 600 mm

• Web Width: 65-330 mm

• Standard Roll Axle: 76 mm / 3”

• Maximum Roll Weight: 60 kg

• Speed: 50 m/min

• Dimensions (WxDxH): 60 x 74 x 109 cm

• Weight without Roll: 30 kg

Available Options:

Integrated Unwinder Model Basic:

• Description: This model includes buffer sensor control, which ensures smooth and consistent

unwinding of the material. The buffer sensor helps maintain optimal tension, preventing issues

such as wrinkling or tearing during the unwinding process.

• Benefits: Enhances efficiency and precision in material handling, reducing downtime and

material waste.Available Options: Continued

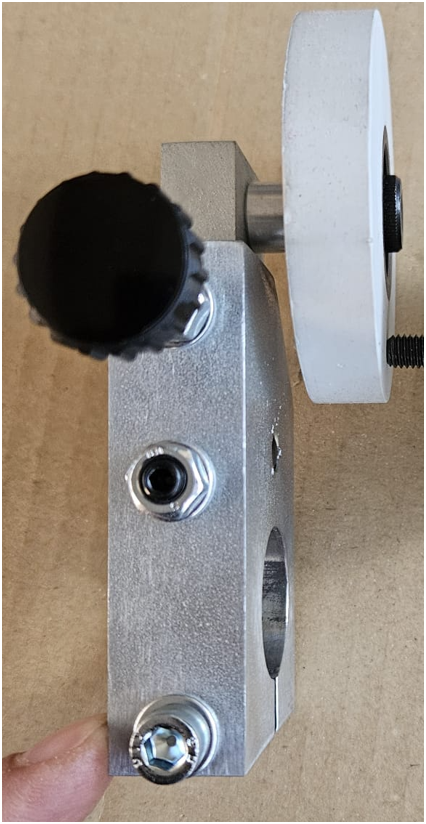

Extra Wheel Holder Unit:

• Description: This unit features a traction rubber wheel, designed specifically for handling

multiple labels simultaneously (3-up job). The traction rubber wheel provides additional grip

and stability.

• Benefits: Improves the handling of multiple labels, ensuring accurate alignment and reducing

the risk of slippage.

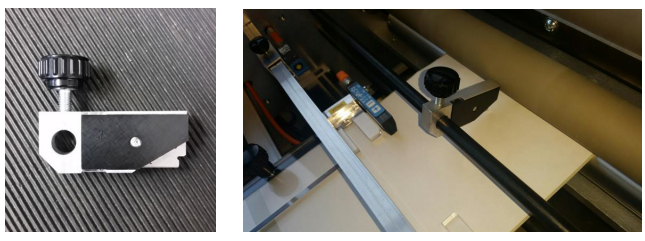

Cue Mark/Hole Reader:

• Description: This reader is equipped with support for detecting and processing cue marks or

holes on the material. It ensures precise positioning and alignment during the folding and

cutting processes.

• Benefits: Enhances accuracy in processing, leading to higher quality output and reduced

errors.

Vertical Slitting Unit:

• Description: This unit includes a razor blade for vertical slitting of the material. It allows for

precise and clean cuts, essential for producing high-quality labels.

• Benefits: Provides flexibility in label design and production, enabling the creation of custom

sizes and shapes.

Standard Razor Blade:

• Description: A spare razor blade specifically for cutting liners. Having a spare blade ensures

that operations can continue smoothly without interruptions due to blade wear.

• Benefits: Minimizes downtime and maintains consistent cutting quality.

• Stainless Plate for Delivery Table:

• Description: This plate is designed for the delivery table and can be removed to accommodate

multi-row jobs. The stainless-steel construction ensures durability and easy maintenance.

• Benefits: Increases versatility in handling different job types and sizes, enhancing overall

productivity.

• Unwinder Adapter:

• Description: This adapter allows the unwinder to accommodate core diameters ranging from

3” to 6”. It provides flexibility in material handling, making it suitable for various roll sizes.

• Benefits: Expands the range of materials that can be processed, improving operational

flexibility.

• Mini Fold Kit:

• Description: This kit enables the folding of labels to a minimum size of 125mm. It is ideal for

producing compact and neatly folded labels.

• Benefits: Supports the production of small-sized labels, catering to specific packaging and

labeling requirements.

Contact

Get in touch with us using the form below. We'll get back to you as soon as possible. Looking forward to hearing from you!