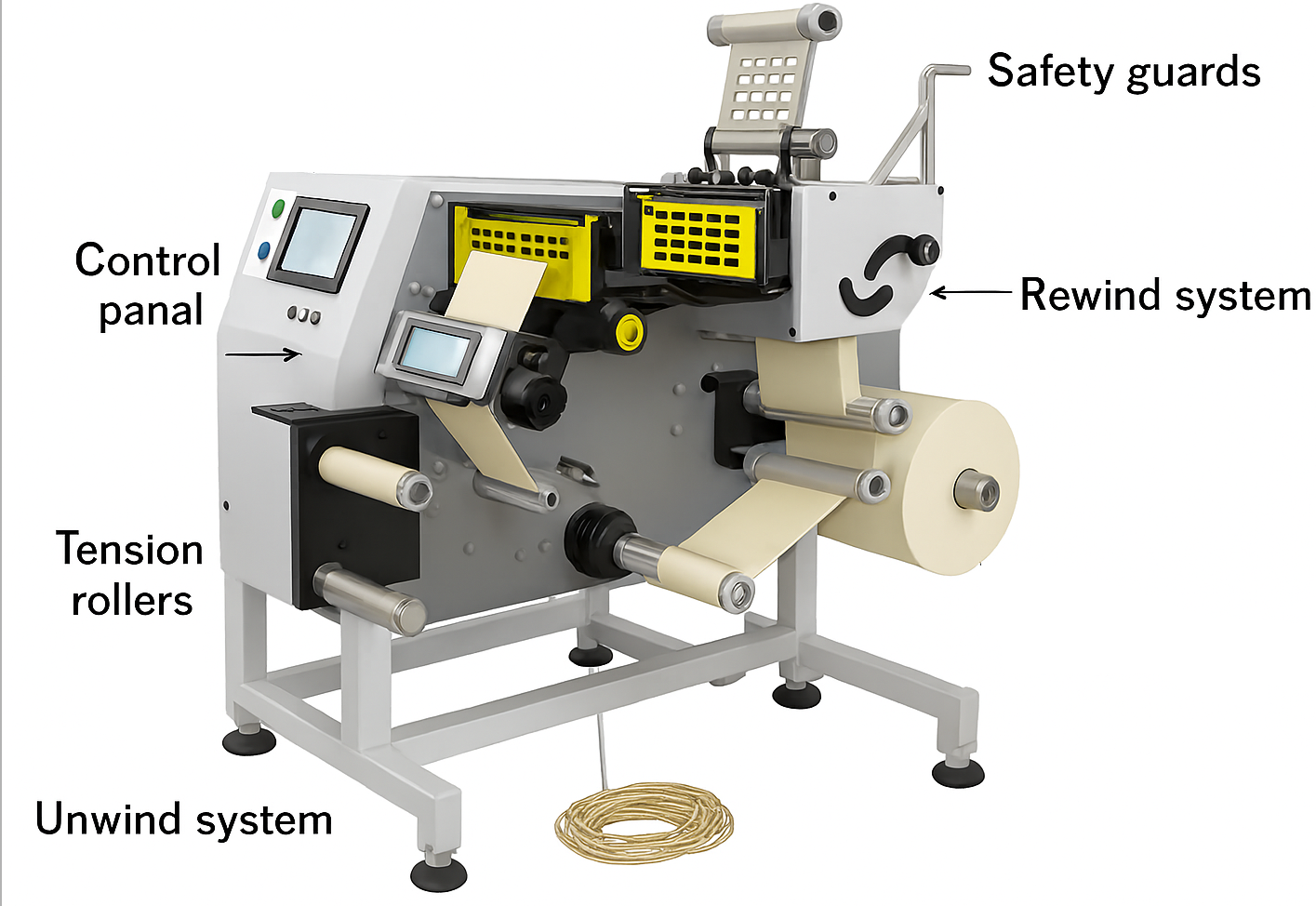

RLS280DIE – Die Cutting & Finishing System

Overview

The Lesko RLS280DIE is a robust, compact, and multifunctional machine designed for efficient production of blank or preprinted labels. It combines die cutting, slitting, and precise rewinding in a streamlined ergonomic system.

Standard Features

Optical label counter with auto slowdown/stop; Electronic meters counter; Finished■roll and total counters; Memory for job settings; Precise tension control; Automatic tension correction; Ultrasonic end■of■roll sensor; Remote diagnostics; Complete tool kit.

Base Parameters

Max web width: 280 mm; Material thickness: 50–200 µm; Materials: paper, laminates, self■adhesive; Max speed: 250 m/min; Register die cutting: 160 m/min (option); Power: 3×400 V; Installed power: ~6.5 kW; Air: ~1 m³/h; Size: 1650×1250×1950 mm; Weight: ~750 kg.

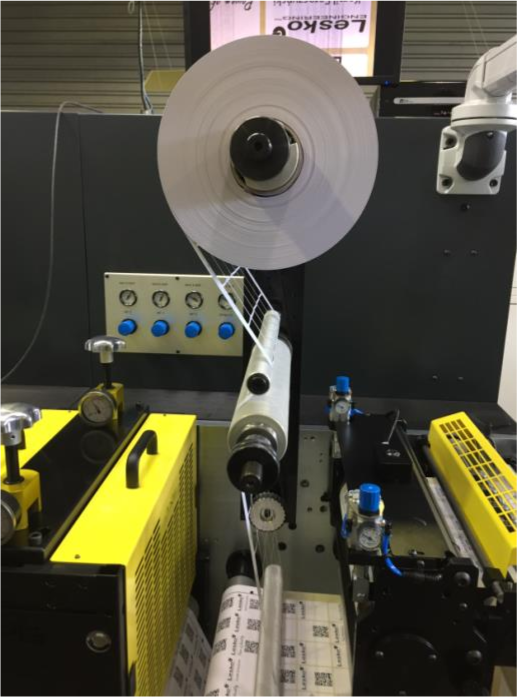

Unwinder

Electromagnetic powder brake; Max roll diameter: 750 mm; Max weight: 120 kg; Ø76 mm shaft; Ultrasonic web guiding; Splice table with pneumatic clamps; Dynamic tension correction; Roll■diameter sensor.

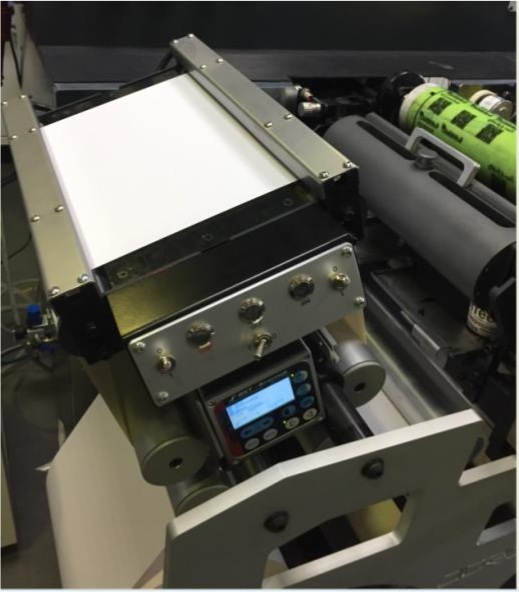

Die■Cutting Unit

Max cylinder width: 280 mm; Magnetic cylinders 60–125T; Includes 80T cylinder; Anvil and support rollers; Hydraulic pressure system KDW■4.

Matrix Rewinder

Driven by main motor; Manual tension; Ø76 mm shaft; Max diameter 500 mm.

Slitting & Rewinding

Manual knife adjustment (min 15 mm); 3 shear■cut sets; Dual rewinder with independent AC drives; Ø76 mm shafts; Max rewind: 400 mm single / 2×290 mm dual.