Proflex Narrow Web Hybrid Printing & Coating Systems,Hot Melt Coating Solutions for Security and Specialty Applications

Narrow Web Hybrid Printing & Coating Systems

Integrated Flexo & Hot Melt Coating Solutions for Security and Specialty Applications

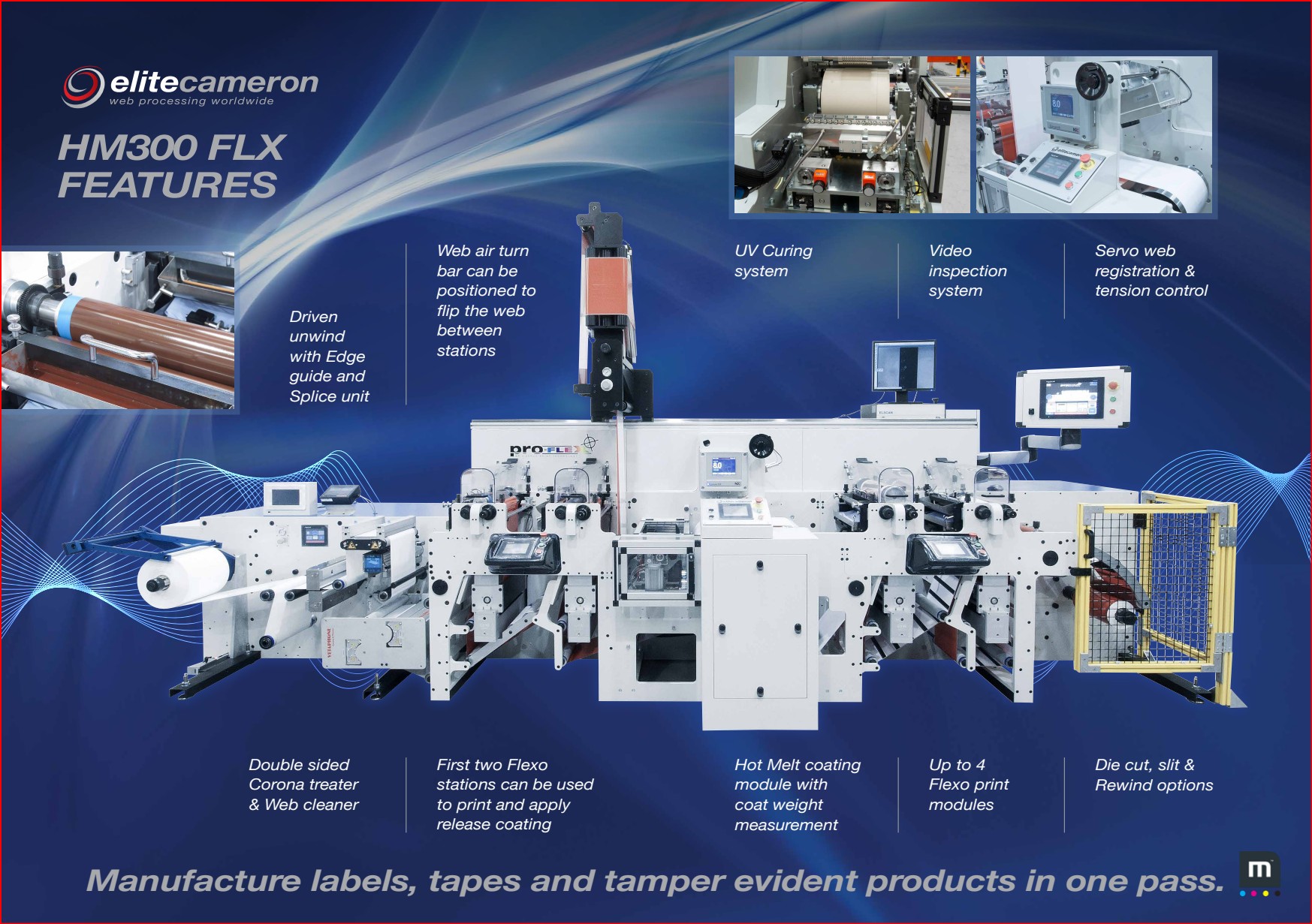

Designed for precision and built for versatility, our Narrow Web Hybrid Printing & Coating Systems seamlessly integrate flexographic printing with advanced hot melt coating technologies, offering a compact, efficient, and cost-effective solution for demanding applications such as security tapes, tamper-evident labels, and specialist packaging.

System Highlights:

- In-line Flexo Printing Modules

Integrated high-resolution flexographic print units for decorative or functional print in a single pass. - Advanced Coating Head

Motorized precision adjustment delivers coat weights from 1 to 200 gsm, ideal for a wide range of adhesives and functional coatings. - Hot Melt Coating System

Featuring heated hoses, a melt tank, and drum unloader, paired with water-cooled coating rolls for precise control and clean application. - UV Drying System

Integrated UV curing with chill rolls ensures rapid setting of UV adhesives and coatings while protecting heat-sensitive substrates. - Unwind & Rewind Options

Available in integrated, single, or multiple station configurations for maximum flexibility. - Servo-Driven Tension Control

Full servo automation with automatic tension control guarantees smooth handling across all substrates at speeds up to 300 ft/min (150 m/min).

Smart Operation & Connectivity:

- Full Servo Drive System

Precision control across all modules for superior accuracy and repeatability. - Touchscreen HMI

Intuitive operator interface with recipe recall and retained settings for fast job setup and changeover. - Remote Diagnostics & Upgrades

Integrated support system allows for real-time troubleshooting and system updates, minimizing downtime.

Efficiency Meets Innovation

Our Hot Melt Coaters leverage decades of expertise in coating technology and web tension control to consistently deliver exceptional results. As adhesive technologies evolve—especially with the rise of UV-curable adhesives—these systems provide eco-friendly, compact, and high-performance alternatives to traditional solvent and water-based systems.

By integrating coating and in-line flexo printing, these hybrid systems deliver a single-pass, cost-effective solution ideal for:

- Security Tapes

- Tamper-Evident Labels

- Specialist Packaging

- Custom Engineered Substrates

With a customizable design, each system is tailored to your unique production requirements—ensuring you’re equipped to meet the challenges of today’s high-performance converting industry.