Multiple Die Cutting Process

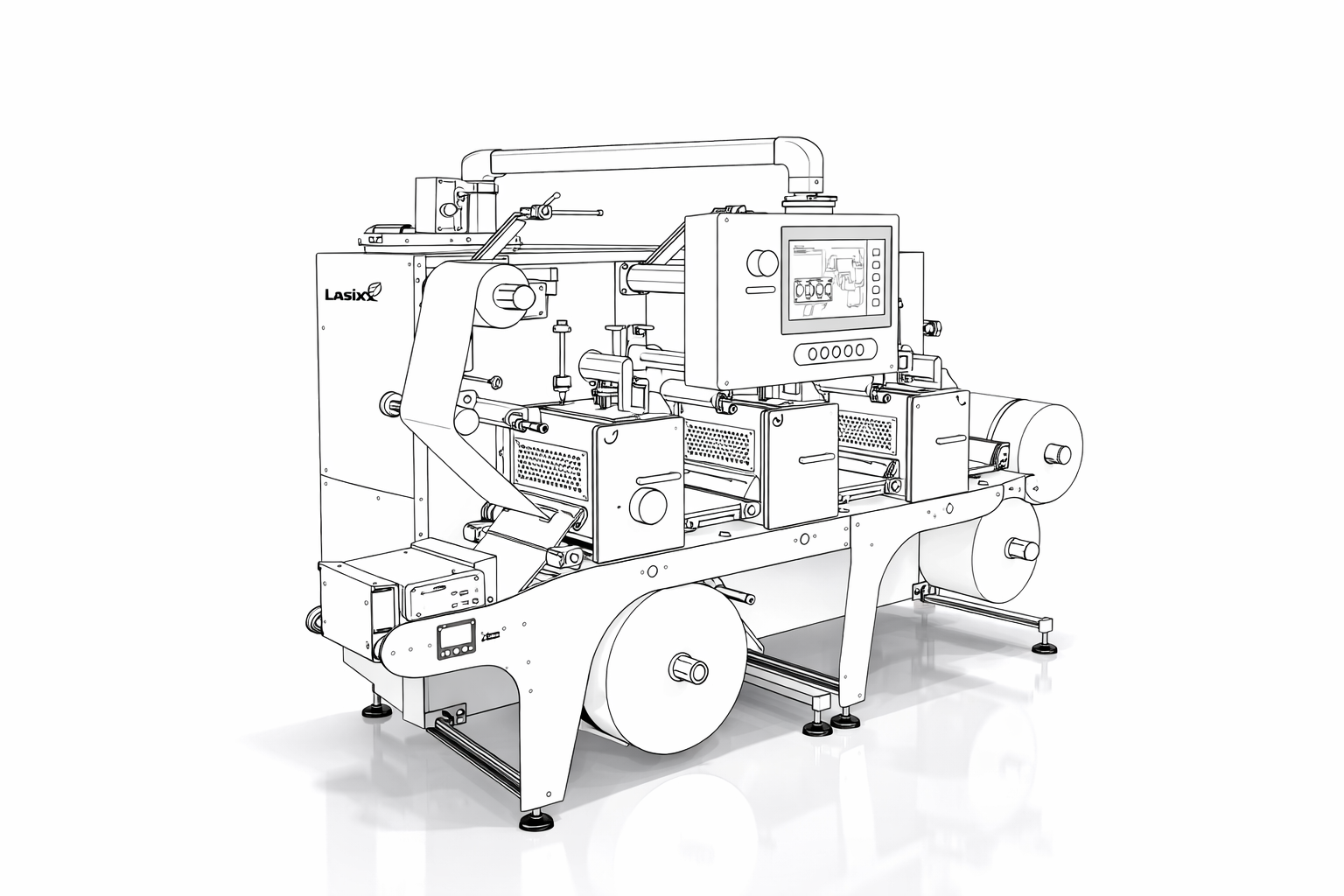

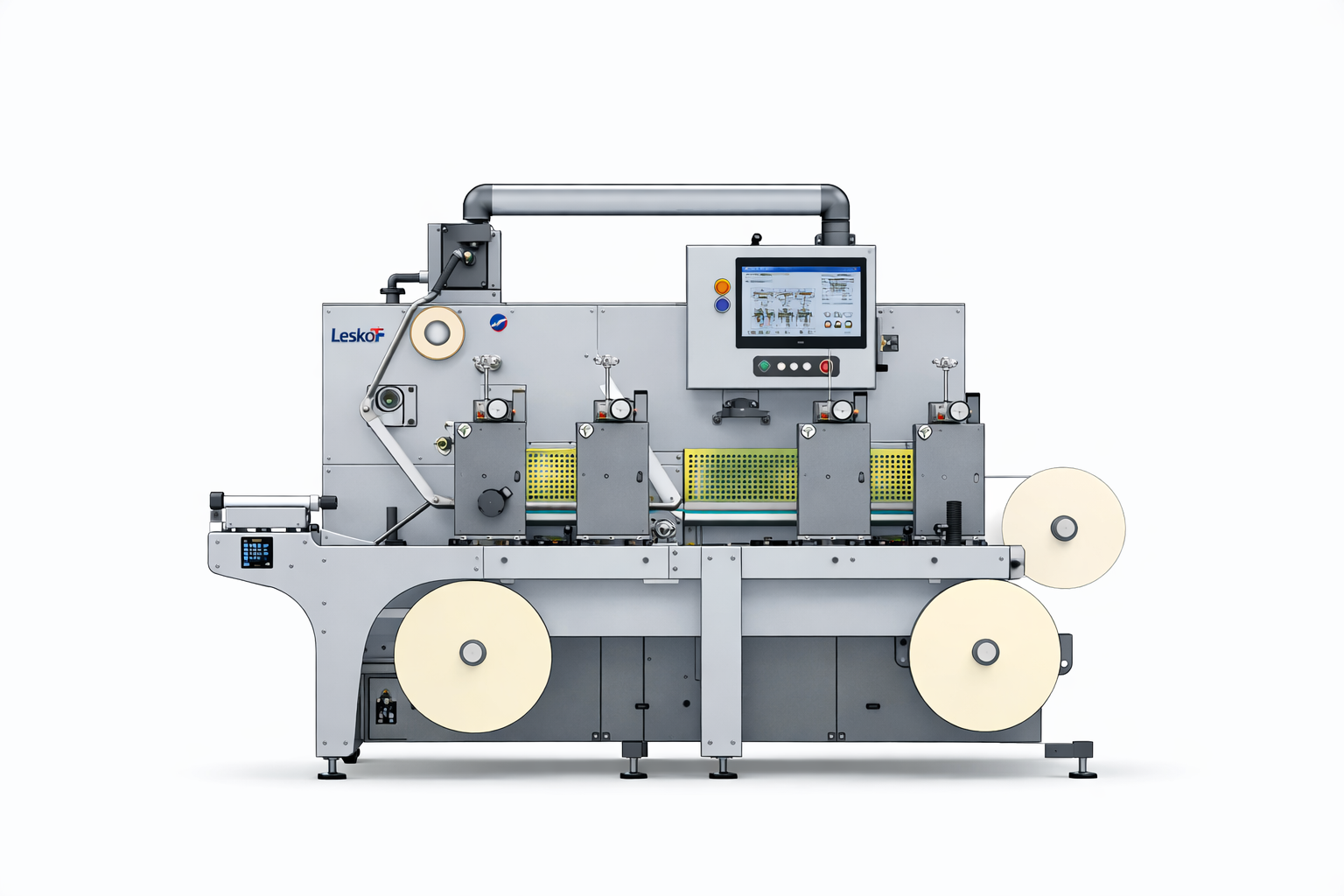

Lesko CL 280-330mm 410mm 3DIE – Custom Multi-Die Label Converting Solution

The Lesko CL 280 3DIE is part of the CL-line modular converting platforms, engineered and built strictly to customer specifications. This fully custom project was designed for a dedicated application requiring high flexibility and precision in the production of specialty labels.

The machine is configured with three servo-driven die cutting units and three matrix rewinders, enabling complex multi-stage converting operations in a single pass. Two of the matrix rewinders can also operate as laminate unwinders, allowing in-line lamination via integrated rubber pressure rollers within the die stations.

All die cutting units are equipped with Mitsubishi Electric servo register systems, ensuring accurate die cutting in perfect registration with pre-printed materials. The system supports high-speed operation while maintaining exceptional precision. The machine is further enhanced with a shear cutting slitting unit and a double-shaft servo-driven rewinder for efficient finished roll handling.

Technical Parameters

-

Maximum web width: 280 mm

-

Material types: Paper, films (PP, PVC, PET), self-adhesive materials

-

Maximum die cutting speed: Up to 200 m/min (material dependent)

-

Power supply: 3 × 400 V / 50 Hz

-

Installed power: ~15 kW

-

Maximum unwinding roll diameter: 600 mm

-

Maximum unwinding roll weight: 120 kg

-

Web guiding system: Electronic web guide from BST International

-

Matrix rewinders / laminate unwinders: Up to 500 mm roll diameter

-

Die cutting units: Servo-driven, adapted to customer magnetic cylinders

-

Slitting unit: Pneumatically clamped shear cutting system

-

Rewinding system: Servo-driven double-shaft rewinder, up to 2 × 450 mm roll diameter