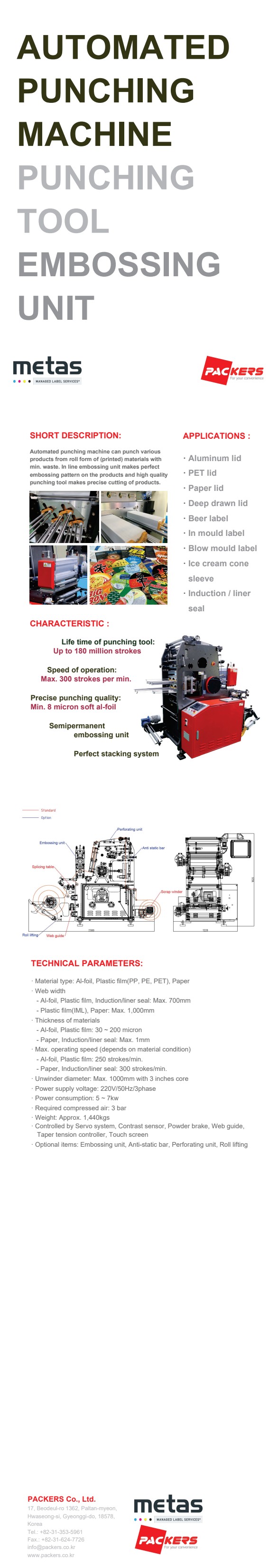

Lid and IML Punching Machines create precise, durable lids and in-mold labels. Cone Sleeve Punching Machines produce cone sleeves for various packaging applications. Induction Seal Punching Machines ensure high-quality induction seals, crucial for product integrity.

Everything about Punching & Cutting for Flexible Packaging Materials

Founded in 1994, PACKERS Co., Ltd. has established itself as a premier manufacturer of converting machinery. The company specializes in a wide range of machines designed for the flexible packaging industry, including:

- Lid and IML Punching Machines: These machines create precise and durable lids and in-mold labels.

- Cone Sleeve Punching Machines: Ideal for producing cone sleeves used in various packaging applications.

- Induction Seal Punching Machines: These machines ensure the production of high-quality induction seals, which are crucial for maintaining product integrity.

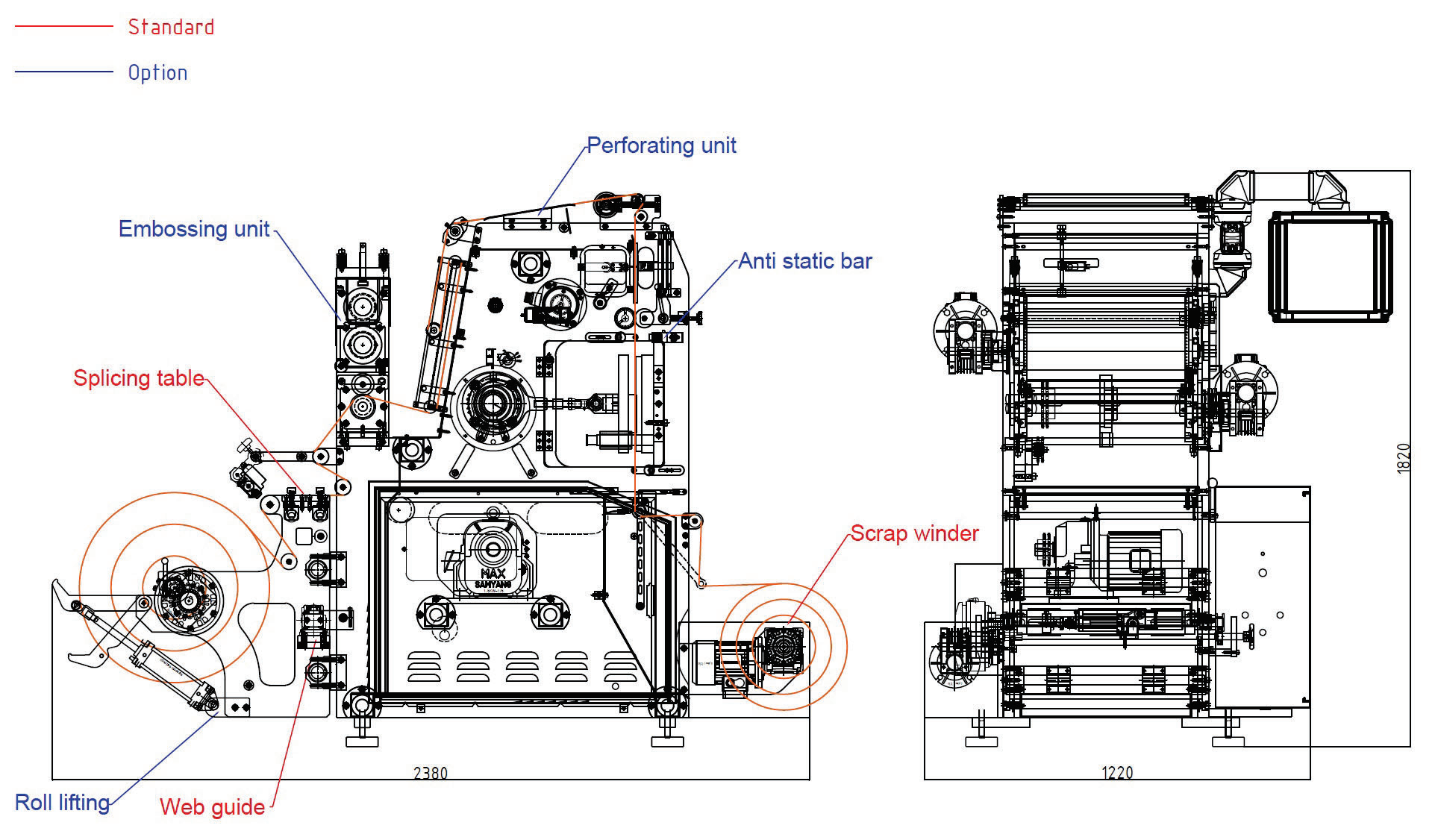

Thanks for sharing the specifications! Here’s a summary of the key details for the SW series models:

- Models: SW-300, SW-450, SW-550, SW-700

- Materials: Aluminium, Paper, PE, PP, PET, and laminated or coated materials

- Material Thickness: 38 microns to 200 microns

- Material Width: 300 mm, 450 mm, 550 mm, 700 mm

- Output: 48,000 to 72,000 lids or IMLs per hour

- Power Consumption: 3 to 7 kW

- Control System:

- Servo motor and drive

- Tension controller

- Powder brake & clutch

- Mark sensor

- Photo sensor

- Touch screen console

- Edge Position Controller (Web guide)

- Ionizer

- Tape detector

- Perforating Machines: Used to create perforations in packaging materials, facilitating easy opening and enhanced user experience.

- Sheet Cutting Machines: These machines are designed for cutting sheets of flexible packaging materials with high precision.

PACKERS Co., Ltd.’s converting machines are utilized by flexible packaging material producers around the globe. These producers create a diverse array of products, including:

- Lids and Labels: For products such as yogurt, cheese, and cup noodles.

- In-Mold Labels and Induction Seals: Used in packaging for coffee, water, juice, tea, and beer.

- Easy-Open Packages: For items like sauce, ice cream, dry milk, and detergent.

- Specialized Packaging: Including lens blisters, medicine, paint, and oil.

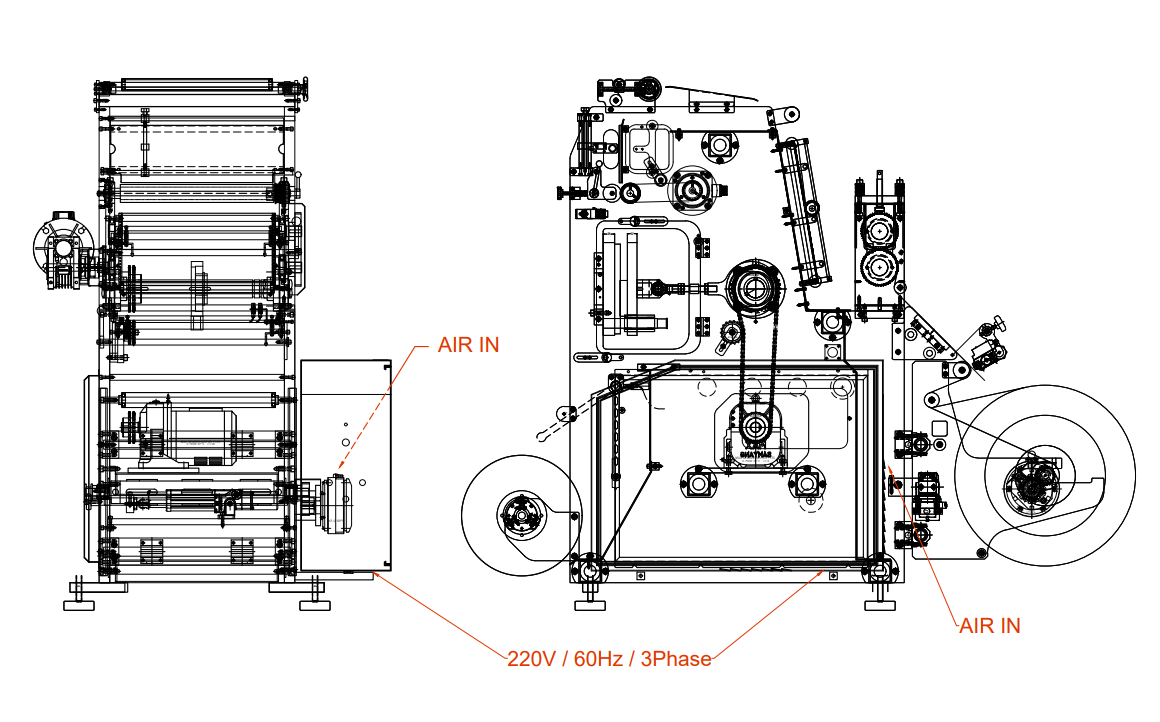

Power ConsumptionElectricity: 220V / 60Hz / 3Phase

Contact

Get in touch with us using the form below. We'll get back to you as soon as possible. Looking forward to hearing from you!