Unwind Rewind Lesko

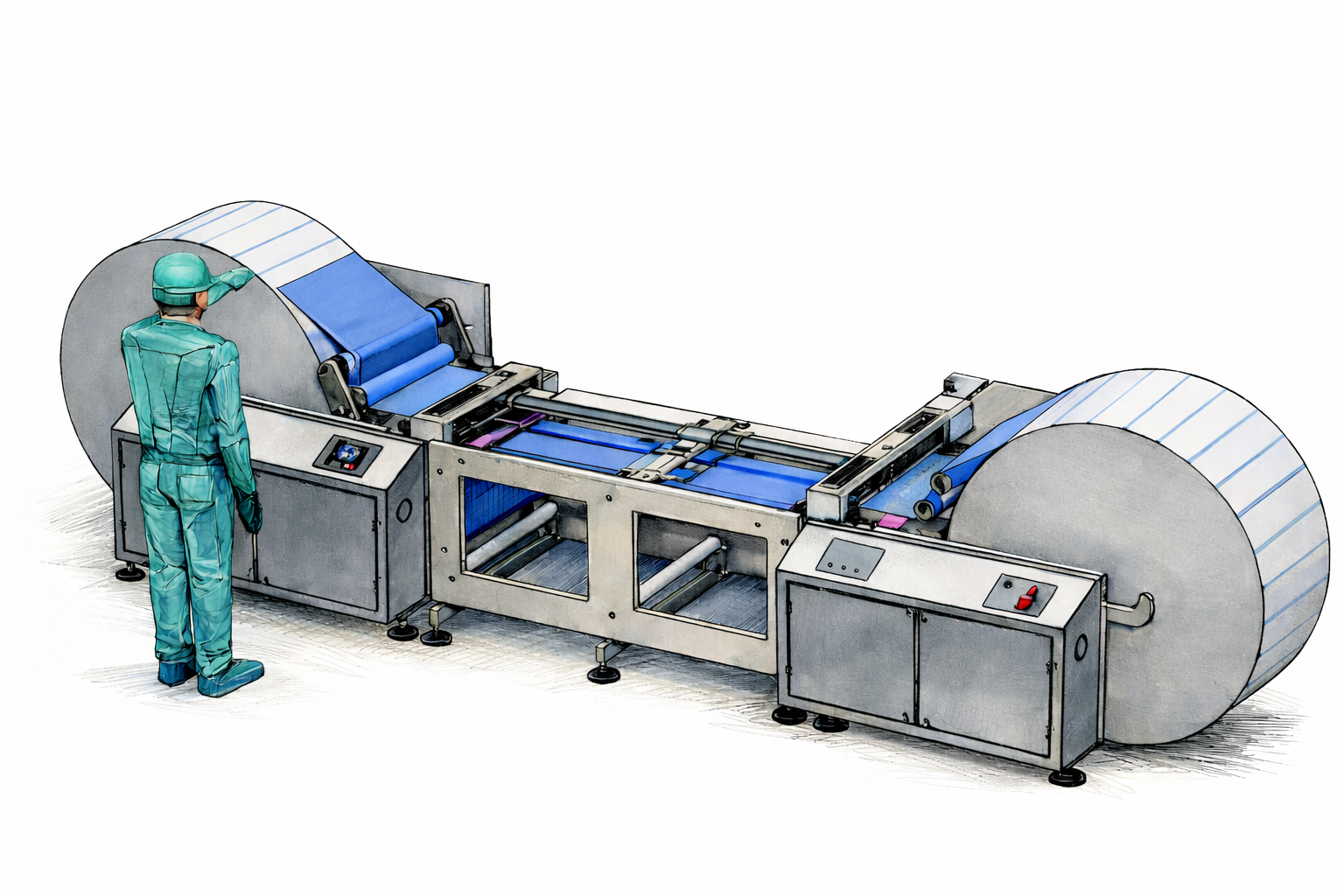

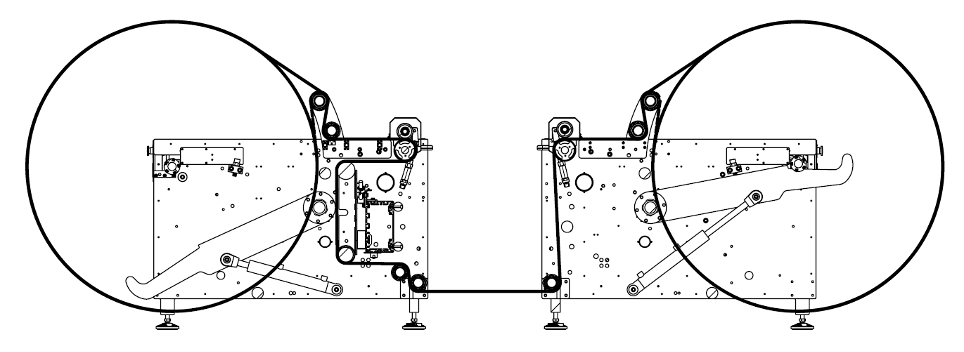

Lesko CL610 – A Modular Platform for Custom Converting Solutions

The Lesko CL610 is more than an unwinder/rewinder — it is a modular converting platform that can be configured to match virtually any converting requirement. Engineered for long-term, stable industrial operation, the CL610 serves as a flexible base system that can be transformed into a purpose-built production line.

With its robust mechanical design and microprocessor-based control system, the CL610 allows customers to build application-specific solutions without compromise.

Possible Special Applications Built on the CL610 Base

🔹 Precision Slitting & Rewinding System

Configured with razor, shear, or crush slitting modules for films, laminates, papers, or label stock. Ideal for high-accuracy roll finishing with controlled tension and clean edge quality.

🔹 Digital Print Finishing & Re-Rewind Line

Designed to handle pre-printed webs from digital presses. Optional inspection, registration control, and rewind diameter management ensure perfect roll presentation for downstream processes.

🔹 Coating, Lamination, or Protective Film Application

The CL610 base can be expanded to support inline coating or lamination modules, transforming it into a compact finishing line for functional films, packaging materials, or specialty substrates.

🔹 Inspection & Quality Control Rewinder

Integrated camera or defect-marking systems allow operators to inspect material while rewinding, making the CL610 ideal for quality-critical applications.

🔹 Lightweight Converting for Medical, Technical, or Specialty Materials

Gentle web handling, precise tension control, and customizable web paths make the CL610 suitable for sensitive or high-value materials.

![Image From nT2001-MTS-2026 CL610 - unwinder - rewinder[75]](https://solutions.metas.global/wp-content/uploads/2026/01/Image-From-nT2001-MTS-2026-CL610-unwinder-rewinder75.png)

![Image From T2001-MTS-2026 CL610 - unwinder - rewinder[75]](https://solutions.metas.global/wp-content/uploads/2026/01/Image-From-T2001-MTS-2026-CL610-unwinder-rewinder75-1.png)

![Image Fromn T2001-MTS-2026 CL610 - unwinder - rewinder[75]](https://solutions.metas.global/wp-content/uploads/2026/01/Image-Fromn-T2001-MTS-2026-CL610-unwinder-rewinder75.png)

![Image From T2001-MTS-2026 CL610 - unwinder - rewinder[75]](https://solutions.metas.global/wp-content/uploads/2026/01/Image-From-T2001-MTS-2026-CL610-unwinder-rewinder75.png)

![Image From ,T2001-MTS-2026 CL610 - unwinder - rewinder[75]](https://solutions.metas.global/wp-content/uploads/2026/01/Image-From-T2001-MTS-2026-CL610-unwinder-rewinder75-2.png)