Focus Inspection Rewind System Machine Reliable, Compact Solutions

Cost-Effective Rewinding & Inspection Systems

Reliable, Compact Solutions for High-Quality Label Finishing

Focus provides two versatile and affordable systems designed for rewinding and manual inspection of printed self-adhesive labels, helping you deliver high-quality, application-ready rolls to your customers. Whether you are a small label producer or a large converter, these machines help streamline post-print processes while maintaining excellent quality control.

Cost-Effective Rewinding & Inspection Systems

Reliable, Compact Solutions for High-Quality Label Finishing

Focus provides two versatile and affordable systems designed for rewinding and manual inspection of printed self-adhesive labels, helping you deliver high-quality, application-ready rolls to your customers. Whether you are a small label producer or a large converter, these machines help streamline post-print processes while maintaining excellent quality control.

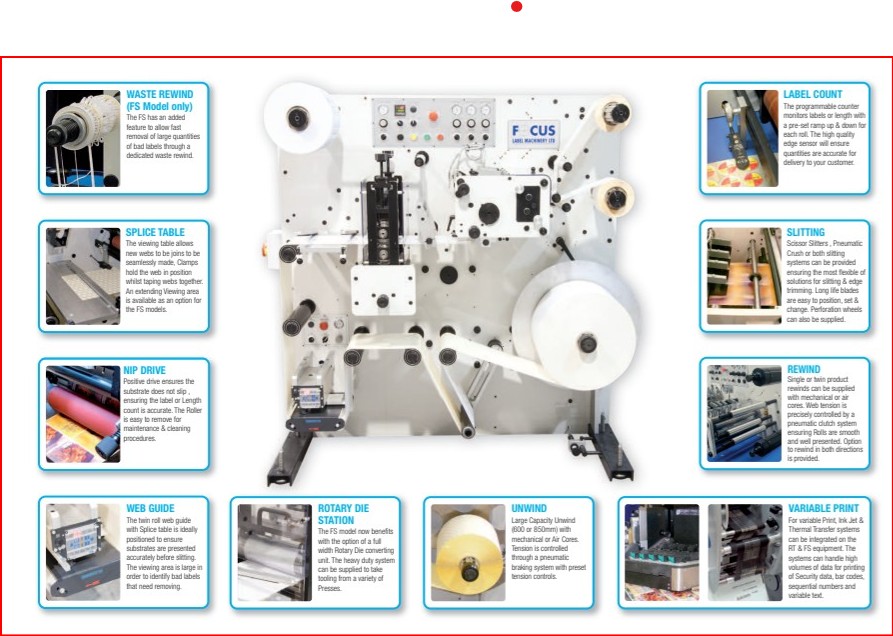

Two Flexible Machine Styles

- Tabletop Model – A compact and space-saving design, ideal for short runs, smaller production environments, or quality control departments.

- Free-Standing Model – A larger, more robust unit for continuous operation, suited to higher-volume production with enhanced capabilities.

Both models are engineered with ease of use and efficiency in mind, offering fast setup, intuitive controls, and low maintenance requirements.

Advanced Features – Standard

Despite their cost-effective nature, these systems come loaded with high-end features typically found on more expensive inspection rewind machines:

- Web Guiding System

Ensures consistent edge alignment during operation, maintaining print registration and roll quality throughout the rewinding process. - Integrated Splice Table

Provides a convenient platform for inspecting, editing, and replacing faulty labels, allowing operators to splice the web quickly and efficiently. - Fully Adjustable Web Tension Control

Offers precise management of tension throughout the unwind and rewind process, accommodating a wide range of substrates without stretching or misalignment. - Slitting Options: Scissor & Crush

Available with both scissor slitting (ideal for clean, sharp edges) and crush slitting (for high-speed and low-maintenance operations), providing flexibility for various materials and applications. - Twin Rewind Shafts

Enables simultaneous rewinding onto two separate cores, increasing throughput and offering convenience for producing multiple smaller rolls. - Label or Length Count Programming

The system can be pre-set to stop automatically based on label count or web length, improving repeatability and reducing waste.

Application Versatility

These systems are suitable for a wide range of applications, including:

- Self-Adhesive Labels – For product packaging, branding, barcoding, and more.

- Tickets – Ideal for event, transport, or retail ticket production.

- Ribbons – Compatible with thermal transfer ribbons and other narrow web substrates.

Customizable Core Sizes

Machines support various core diameters, allowing users to produce finished rolls that are directly compatible with customers’ automatic or semi-automatic application systems.

The Focus Advantage

Backed by decades of experience in the printing and converting industry, Focus machines are designed and built in-house, combining reliability, precision engineering, and low cost of ownership. These rewinding and inspection units are no exception—giving label converters a professional-grade solution without the premium price tag.