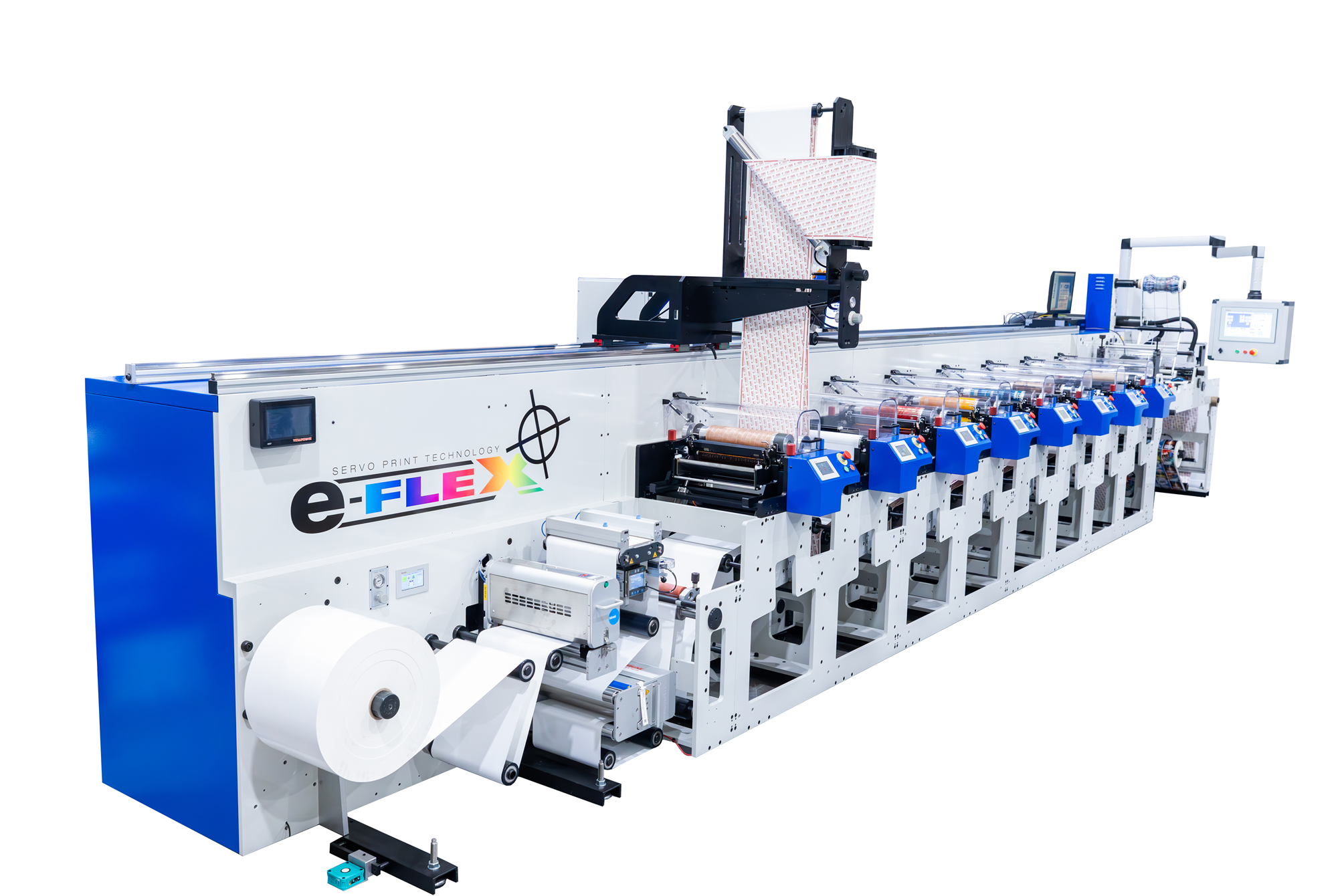

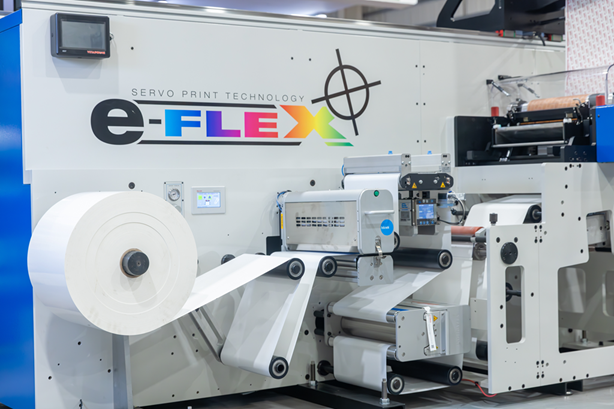

e-Flex platformOptimized Production: The e-Flex SERVO ensures minimal downtime between jobs, providing precise repeatability and high-quality print across a wide range of substrates and applications.

The e-Flex printing press offers a range of advanced features designed to maximize efficiency and reduce downtime. Here are some key highlights:

Specifications

- Web Width: 330mm-430mm

- Number of Colours: 2 to 12

- Min Print Length: 7” (178mm)

- Max Print Length: 20” (508mm)

- Max Unwind: 1000mm

- Max Rewind: 800mm

Key Features

- Servo Print Technology: Each print station has two separate servo drives for web impression and print cylinder control, ensuring precise tension management and accurate print-to-die cut alignment.

- Energy Management: Utilizes the latest digital drives and ink-drying systems to reduce energy consumption by focusing energy where it’s needed.

- HMI (Human-Machine Interface): Touch screen interface for easy setup and storage of job data, allowing quick recall for repeat runs.

- Pre-Register & Impression Setting: Automatic register positions and precision micro adjustments optimize print quality without wasting material.

- Auto Register: Maintains stable and accurate register control without operator intervention, even on unsupported substrates.

- QC Job & Colour Changes: Open architecture print head design allows for quick color and job changes without wasting material.

- Substrates: Capable of converting a wide range of substrates from 30 to 380 microns, including unsupported films and various label stocks and carton boards.

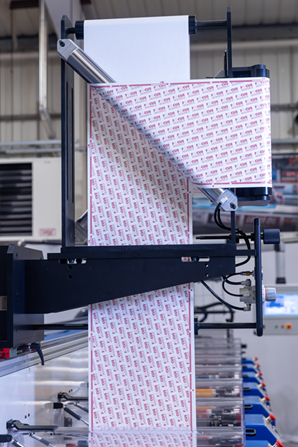

- Converting Options: Rail-mounted ancillary systems provide flexibility for positioning various converting applications.

Additional Options

- Drying Systems: IR, UV, or LED

- Chill Rolls: Optional

- Rotary Die Stations: Yes

- Slitting: Yes

- Digital Ink Jet Module: Optional

- Other Options: Turn bar, Delam/Relam, Lamination, Cold foil, Hot foil, Rotary silk screen, Sheet stacker, Corona treater, Web cleaner, Auto register, Fan folder, Ticket streamer, U.V drying, Chill rolls.

This comprehensive set of features makes the e-Flex a versatile and efficient tool for various printing and converting needs. If you have any specific questions or need more details, feel free to ask!

The e-Flex Platform is designed to be a versatile and highly efficient solution for flexographic printing, particularly suited for labels, security labels, films, packaging, tickets, and cartons.

Key Highlights of the e-Flex Machine:

-

Twin Servo Technology: Ensures independent control of both the substrate and printed image, improving precision and reducing setup time.

-

One-Touch Setup & Pre-Register: Speeds up job changeovers, minimizing waste and improving production efficiency.

-

Modular Platform & Rail System: Allows for customization with various optional features to suit specific applications.

-

Choice of Web Widths: Starting from 330mm (e-Flex 330-1) and scalable to wider configurations.

-

Combination Drying Systems: Supports UV, LED, and IR drying for different ink and substrate requirements.

-

Versatile Converting Options: Compatible with both Roll-to-Roll and Roll-to-Sheet converting.